Committed To Creating High-Quality Cosmetic Packaging

Established in 2004, Jasmine packaging has become a leading manufacturer of cosmetic packaging and a trusted OEM partner for many well-known brands.

Over the past 20 years, we have understood the changing needs of our customers and have continued to innovate and improve to provide quality solutions while remaining at the forefront of trends in the beauty industry.

At Jasmine Packaging, we believe that change is necessary for growth and success, and we view change as a catalyst for progress.

Cosmetic Packaging Manufacturer

We specialize in manufacturing and distributing cosmetic packaging, focusing primarily on designing and developing Perfume Bottle and Twist/Click Cosmetic Pen styles for the wholesale market, offering the world’s most comprehensive design collection.

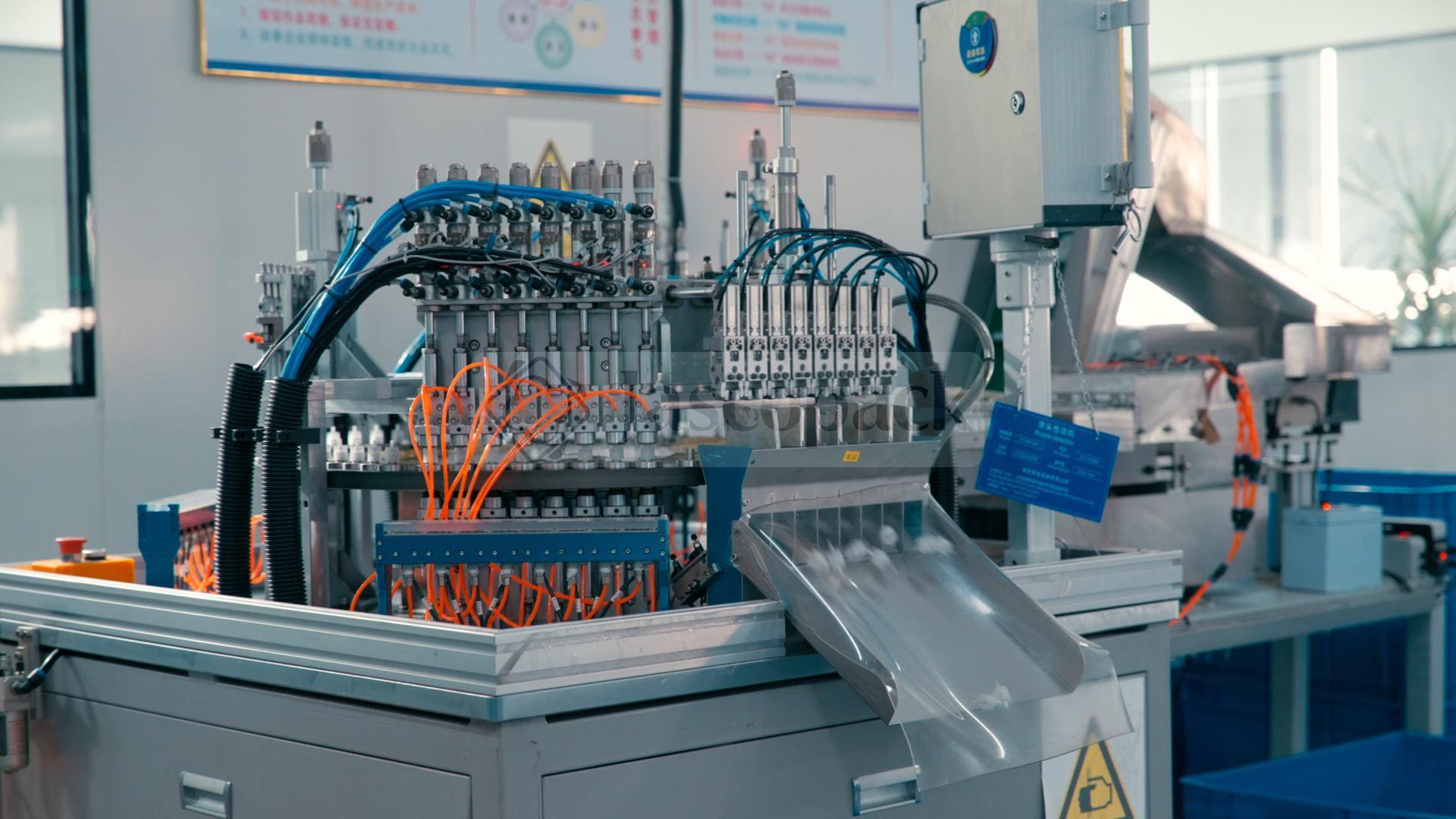

Jascopack’s factory offers custom mold development with automated production lines, conducting 100% quality inspection on every cosmetic packaging item.

Cosmetic Packaging Production Process Video

Our workshop maintains a stock of thousands of molds, having provided mold manufacturing services for over 60 brands. We deliver consistent quality and uniquely tailored designs to our partners.

Using a press machine and molds, aluminum sheet raw materials are repeatedly stamped into shape, enabling rapid, high-precision mass production of aluminum and plastic components.

After stamping and before polishing, trim the edges of aluminum parts to achieve a smooth surface and remove burrs. This ensures subsequent casings lie flat and integrate with other components.

Through automated mechanical dust removal and grinding processes applied to aluminum surfaces, each aluminum component can rapidly achieve a mirror-like polished finish.

This process relies on a chemical reaction between the aluminum or aluminum alloy and a chemical agent to form a colored protective layer. This reaction extends the service life of the aluminum.

We operate dozens of automated injection molding machines that rapidly produce plastic components in bulk by injecting molten plastic into molds, where it cools and solidifies.

By integrating processes such as assembly and inspection, and utilizing automated and semi-automated handling of different components, a single machine achieves a production speed approximately 30 times faster than manual labor.

Automated inspection equipment maintains product quality at a baseline standard, while final manual re-inspection allows human eyes to identify defects that machines cannot detect.