Committed To Creating High-Quality Cosmetic Packaging

Established in 2004, Jasmine packaging has become a leading manufacturer of cosmetic packaging and a trusted OEM partner for many well-known brands.

Over the past 20 years, we have understood the changing needs of our customers and have continued to innovate and improve to provide quality solutions while remaining at the forefront of trends in the beauty industry.

At Jasmine Packaging, we believe that change is necessary for growth and success, and we view change as a catalyst for progress.

Production Process

Injection

InjectionPlastic granules are dried, heated and melted, injected into the mold cavity, cooled and molded, and then demolded to form plastic structural parts.

Punching

PunchingPunching is a metal forming technique in which aluminium sheets are pressed into certain shapes, sizes and properties by means of a press and a die.

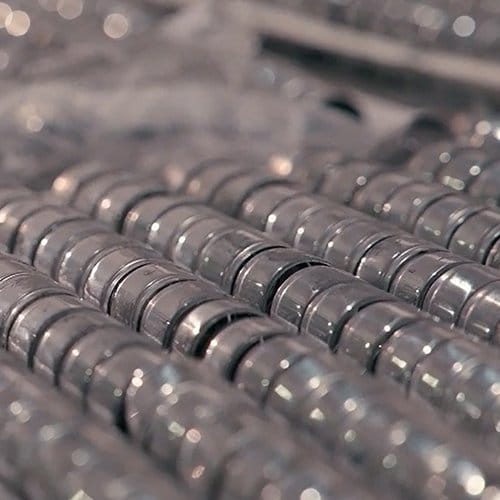

Polishing

PolishingAfter stamping, aluminium products are mechanically polished to make the surface smooth and clean.

Oxidation

OxidationThe polished aluminum products need to go through the process of lanyard, cleaning, electropolishing, anodizing and dyeing.

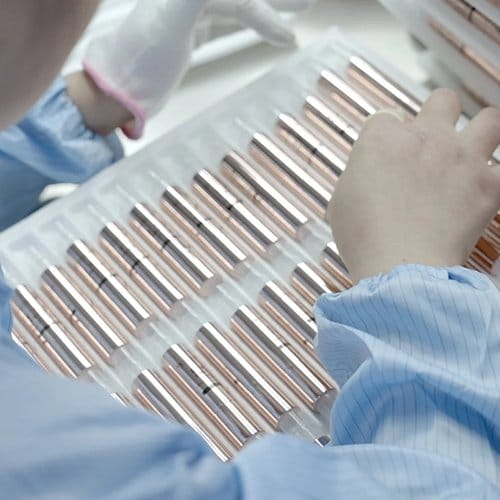

Aluminum Full Inspection

Aluminum Full InspectionAfter the aluminum parts are oxidized and baked in the oven, it is necessary for the quality inspectors to look at the surface one by one to check for defects.

Assembly

AssemblyAfter the assembly of each component is completed, check that the function is running normally and qualified before packaging for shipment.

Dust-free Assembly

Dust-free AssemblyDust-free assembly is key to our production, and the environment is strictly controlled to prevent dust and contaminants from entering.

Shipment

ShipmentWe have a comprehensive warehouse management system and well-managed dedicated warehouses for raw materials and finished products.